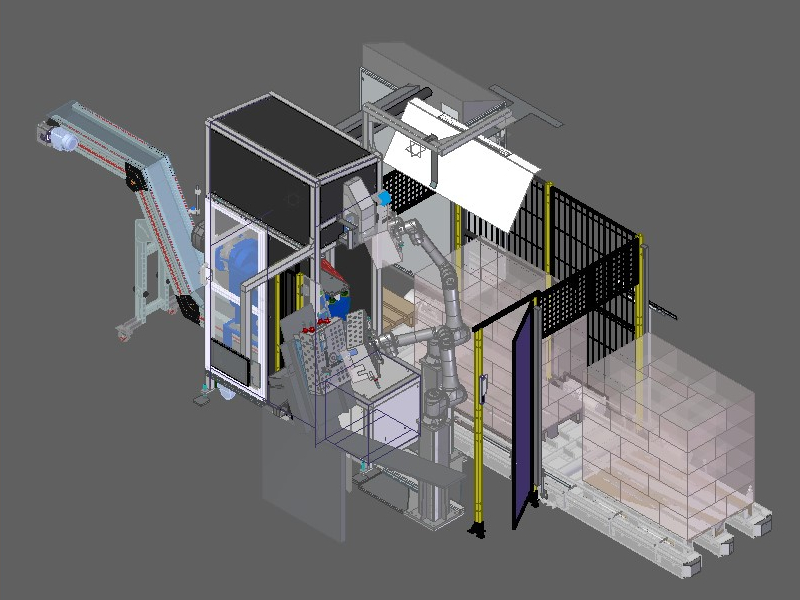

Connecting compressors to the production line of refrigerators and freezers is a strenuous and highly repetitive process due to the weight of the product. One of the global leaders in home appliance manufacturing has asked us to implement a system that ensures both high reliability and versatility in loading compressors from wooden pallets to technological pallets on the production line conveyor.

We have developed a robotic system that integrates two industrial robots and an Autonomous Guided Vehicle (AGV), which serves as both a "smart" warehouse and a loading machine.

Within the system, 10 pallets containing different compressor models are placed in "rest" (storage) positions or "work" positions near the first of the two anthropomorphic robots. The complex logic for pallet allocation incorporates information from the production request of the assembly line and input from operators, with the goal of making the required compressor models available to the first anthropomorphic robot. The AGV, capable of transporting loads up to 1300kg, facilitates the reallocation of pallets. The exchange of empty and full pallets between the robotized island and the outside is carried out by warehouse operators and ensured by a meticulous safety system.

Using a 2D vision system and a 3D system, the first anthropomorphic robot retrieves compressors from the pallets and loads them onto a set of 15 transports, which serve as a buffer for the second anthropomorphic robot. The second robot is responsible for the actual loading of compressors onto the technological pallets on the production line.

Through the high integration of sensing technology, traditional and innovative robots, we have created a highly reliable and versatile system.

The supply of packaging cases to filling machines is a tiring and repetitive task, as it involves moving heavy cardboard boxes weighing over 15kg and their contents. One of the global leaders in the Food & Beverage market, needed to automate and make this process reliable.

We created a robotic system consisting of two collaborative anthropomorphic robots that work together to open the cardboard boxes and empty the packaging cases into the downstream production line warehouse, using an ultrasonic cutting system.

The first collaborative robot, guided by a 2D camera and a distance sensor, picks up the boxes containing the packaging cases from a pallet. Each picked box is slid along the entire perimeter of the lid on a vibrating blade activated by ultrasonic stimulation. Once the cut is complete, the robot positions the box under a set of suction cups, which remove the lid.

During this phase, the two cobots move in coordination to ensure that the first robot empties the packaging cases from the box into the tool of the second robot. The first robot performs gentle movements to slide out the box and then disposes of it in a shredder.

The second anthropomorphic robot aligns with the downstream warehouse and deposits the packaging cases onto a chute.

Thanks to a complex integration between the two anthropomorphic robots and sensors, the process has been reliably automated with an ergonomic layout.

The assembly process of heat pump evaporators involves a lot of complexity: from the variability in dimensions and types of different codes to the management of gasses to achieve the correct flame shape and temperature for welding. This project relies heavily on a manual and artisanal approach which is very operator dependent.

The integration of innovative technologies such as vision systems, collaborative robotics, and software that manages component supply and line movements has led to the complete automation of the evaporator components insertion and welding process.

Not only the process is fully automated, but it is also capable of handling a wide variety of different product codes.

By utilizing vision systems and algorithm mapping, the system can adapt to different evaporators in terms of size, curvatures, and materials.

The quality of espresso is not only related to the taste of coffee but also to other physical parameters, including the overall liquid amount and temperature The amount of coffee dispensed from a capsule depends on various process parameters involved in its production.

Therefore, it is essential to monitor the production process. In recent years, the quality of the process has been verified by dispensing capsules using actual coffee machines. However, these machines inherently have variations. The Customer needed to test coffee capsules using a repeatable and industrial system.

We developed a testing bench that simulates the operation of a coffee machine.

Periodically, a collaborative robot takes a coffee capsule from a storage drawer, weighs it using a precision scale, inserts it into the Brewing Unit of a coffee machine, checks with a 3D camera that the capsule is correctly positioned in the housing, closes the Brewing Unit, and initiates the dispensing process.

A pump pressurizes the hydraulic circuit, while resistors heat the water. At each instant, the bench measures the pressure in the circuit and, based on a pressure/flow curve defined during the study phase, sets the water flow passing through the coffee capsule using a high-precision regulation valve.

The coffee is weighed from the first drop that falls into a collection cup using a scale. When the target weight of the espresso is reached, the bench records the dispensing time. During dispensing, a real-time camera reads the flow and color of the coffee to derive additional quality parameters.

All data is saved in the client's management system, providing a large amount of qualitative and quantitative information about the process.

Quality control is a crucial aspect in the food industry. An Italian company operating in the coffee industry needs to ensure the quality of each individual coffee capsule produced.

The main quality defects that can occur in capsule production relate to the assembly quality of the lid onto the tray containing the coffee. Incorrect lid positioning or faulty welding can result in compromised coffee quality or, at best, an aesthetic flaw.

We have developed a vision system consisting of a 2D camera and a lighting system that enables real-time inspection of up to 8 capsules per second using complex algorithms.

The system is integrated onto the conveyor belt after the filling machine and is capable of rejecting defective capsules before they reach the packaging area.

A company with a long-standing experience in manufacturing automatic grease dosing pumps needed to automate two phases of the production process: filling the pump tanks and testing the pumps.

We have developed a bench that automates the filling and testing phases for pumps, leaving the operators with the sole task of loading and unloading the pump under test.

Thanks to a project designed to be flexible, the system can process various pump sizes and types of grease.

The filling and testing procedure is straightforward: after manually loading the pump onto the bench, the system performs a functional test on it. Once all the checks are passed, the pump is filled, and a label with the test results is printed.

At this point, the operator can unload the pump and load the next one.

This way, the customer has significantly increased both the quantity and the quality of the outgoing pieces.

In the food industry, as well as in manufacturing, at the end of the production process, there is a need to insert and package products into cartons for distribution.

An Italian coffee company has asked us to optimize the loading and packaging phase of coffee bean bags into transport boxes.

Loading the flat cartons onto the packer machine is a tiring, repetitive, and completely manual task, despite its low added value.

Operators assigned to this task could be allocated to more important and strategic operations, instead of engaging in exhausting work.

By integrating sensors and collaborative robotics solutions, we have developed a system capable of automatically loading cartons onto the packaging line, independently managing any carton format loaded on a pallet (with different configurable types).

Specifically, the system is able to:

The automatic carton supply system we developed ensures accurate quality control and efficient handling of carton loads. By optimizing the packaging processes, it enables a smoother workflow and overall improved productivity.

To effectively respond to the typical variables of a packaging line (positions, quantities, weights, and carton formats), our Research and Development laboratory has designed and implemented a gripper capable of adapting to different situations without the need for manual intervention to replace the manipulator or reprogram the system.